Top 10 Industrial Automation Applications for Any Factory

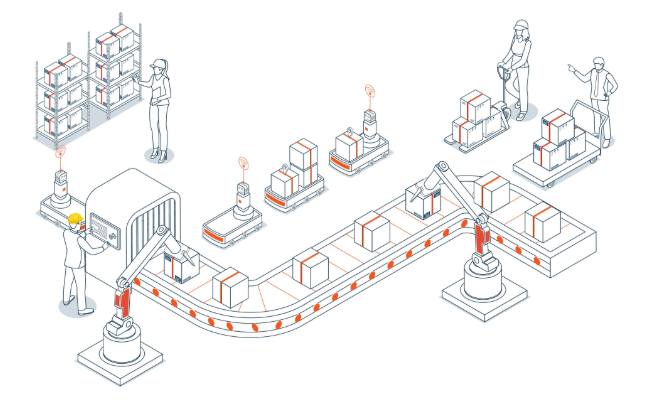

Manufacturers often ask: Where should we start with automation? With tight budgets and limited time, identifying the right first step can make or break your success. The good news? Many of the most common industrial automation applications are also some of the simplest. These applications are ideal for introducing automation in a way that’s cost-effective, low risk, and immediately impactful.

And when the right task is automated, the benefits are hard to ignore.

Shorter lead times. Fewer bottlenecks. More consistent output. Whether it’s packaging, assembly, or machine tending, we’ve seen time and again how even basic automation can free up valuable resources and deliver fast results, especially for small and midsize manufacturers.

Below, we explore 10 practical automation applications found in real factory settings. These are all tasks that can be tackled with off-the-shelf technologies like cobots, vision systems, or even complete plug-and-play robot cells.

Not sure where to begin? Our free, 5-step guide on getting started with automation breaks down how to move from idea to implementation.

Industrial Automation Applications You Can Implement Now:

1. Palletizing in Industrial Automation

One of the most widely adopted applications, palletizing involves stacking boxes, crates, or products onto a pallet at the end of a production line. It’s repetitive, physically taxing, and highly structured. It’s a perfect fit for automation.

Why automate palletizing?

Reduces risk of injury

Handles high throughput without fatigue

Ensures consistent stacking patterns

Entry-level palletizing cells are widely available, with complete solutions starting for less than $18,000. Explore how manufacturers automate palletizing using low-cost, ready-to-deploy systems.

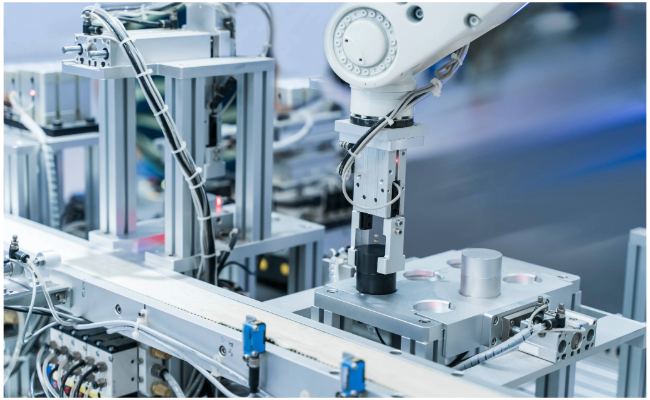

2. How Pick and Place Systems Speed Up Production

Whether you’re moving small parts between stations or transferring finished goods into boxes, pick-and-place automation can significantly reduce cycle times.

Common examples include:

Picking components off a conveyor

Sorting parts into trays

Loading/unloading test equipment

Lightweight cobots and gantry systems for pick and place can be configured online, with entry-level systems available under $9,000.

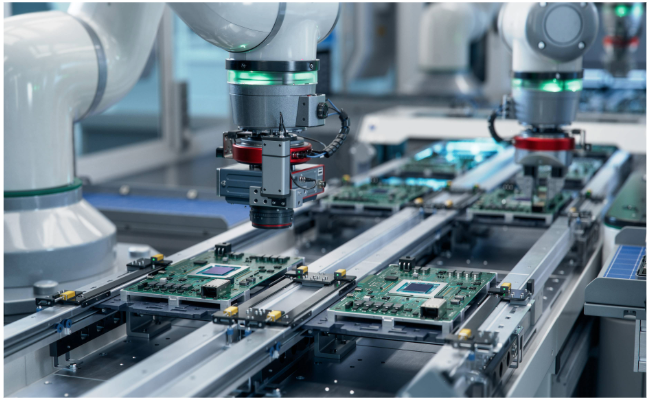

3. Automating Assembly Tasks for Greater Consistency

Robots are increasingly used for precise, repetitive assembly tasks, especially in electronics, automotive, and consumer goods manufacturing.

Typical assembly applications:

Inserting components

Press-fitting

Simple fastening

Affordable options like the igus ReBeL® offer 6-axis flexibility at an entry price point under $8,000. These compact arms make it easy to start automating without needing a six-figure investment.

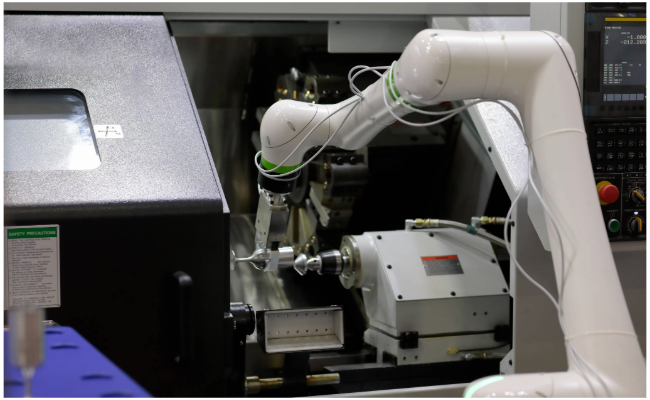

4. Machine Tending: Reducing Downtime with Robots

Machine tending, which is the process of loading and unloading CNC mills, CNC lathes, or injection molding machines, is time-consuming and often inconsistent when done manually.

Benefits of automating this task include:

Better machine utilization

Fewer operator errors

Night shift or lights-out operation

Use our free Machine Planner to configure a CE-compliant robot cell with transparent pricing.

5. Smarter Material Handling on the Factory Floor

Material handling covers a broad range of movements: transferring raw materials, moving work-in-progress, or positioning finished goods.

What makes this task ideal for automation?

It's highly repetitive

Can involve heavy or awkward parts

Often a bottleneck in growing factories

From belt-driven gantries to collaborative carts, there are affordable options even for factories without AGVs or large budgets.

6. Welding Applications for Repeatable Quality

Welding requires precision and consistency, which are both strengths of robotic systems. Automated MIG, TIG, and spot welding cells are becoming more accessible to small manufacturers.

What to automate:

Short, repeatable welds on fixed paths

Fixtures with minimal variation

Tasks in confined or hazardous spaces

Prebuilt welding cells with built-in safety are available on marketplaces like RBTX.com, often priced well below traditional solutions.

7. Using Vision Systems for Quality Inspection

Vision-based inspection is one of the fastest-growing automation categories. Cameras can now detect surface defects, verify dimensions, and adapt inspections in real time.

Benefits of automating inspection:

100% inline quality checks

Traceable digital records

Non-contact verification

Vision inspection kits integrate easily with cobots, with vision sensors starting under $3,000.

8. Packaging Tasks That Benefit from Automation

Packaging involves several micro-tasks: folding cartons, placing products in trays, sealing bags, all of which are tedious for human workers and easy to standardize.

Start simple by automating:

Tray loading

Box forming or sealing

Bag placing

Configurable packaging cells help reduce ergonomic strain and scale with growing demand.

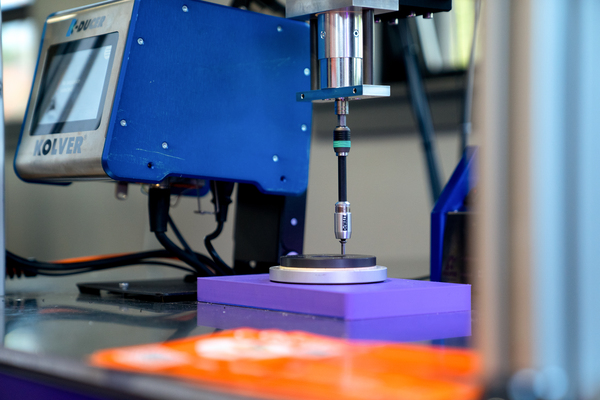

9. Screwdriving Robots in Assembly Lines

Automated screwdriving ensures consistent torque, alignment, and speed, which is critical for quality assurance in electronics, appliances, and metal assemblies.

Common screwdriving uses:

Device enclosures

Panel fasteners

High-mix, low-volume production

Many plug-and-play solutions include integrated torque control and start below $12,000.

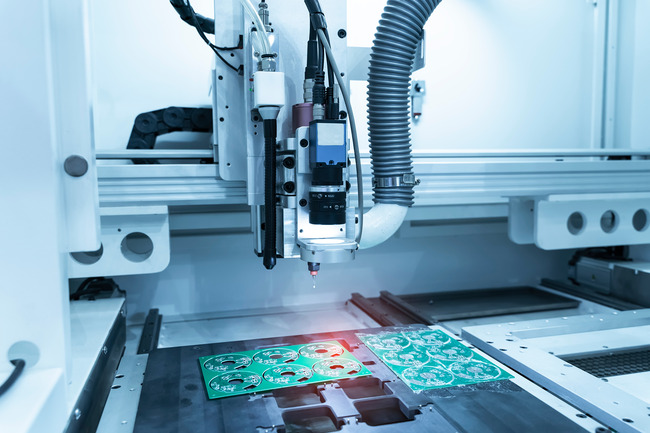

10. Dispensing with Accuracy and Efficiency

Dispensing — gluing, sealing, or applying fluids — is another repeatable process that benefits from automation.

Why automate dispensing?

Reduces waste and mess

Improves bead consistency

Handles complex paths with ease

Pre-integrated dispensing kits simplify glue applications and work seamlessly with lightweight robots.

Try our gluing & dosing robot configurator to quickly design a gluing robot tailored to your specific needs.

Why Start with Simple Tasks?

We often tell customers: just start. Automating even one small task builds internal confidence, gets your team comfortable with the tech, and starts paying off quickly.

Many of the tasks above — pick-and-place, palletizing, dispensing — don’t require custom systems or six-figure investments. And with platforms like RBTX, you can:

Compare options from multiple suppliers

Get transparent pricing up front

Access pre-configured robot cells or build your own

Still deciding where to begin? Book a free consultation with one of our automation experts to assess your task and budget.

FAQ: Industrial Automation Applications

What are the most common industrial automation applications? Tasks like palletizing, pick and place, machine tending, and packaging are among the most widely automated because they’re structured and repetitive.

How much does it cost to automate a single task? Entry-level robot arms start under $8,000, while plug-and-play cells for palletizing or screwing can range from $12,000–$18,000.

Can I automate just one process without overhauling everything? Yes. Many factories start by automating just one bottleneck to learn, build buy-in, and grow from there.

What’s the best place to start with automation? Start with something repetitive, rule-based, and easy to define, which is often at the end of a production line. Our Machine Planner tool can help you design a complete solution online.